Refined Practices: Survey Technology through the Years

/SSM has been at the forefront of surveying expertise since 1932. Since then, we’ve consistently refined our practices and pioneered into the newest technology, ensuring our survey data is always collected proficiently and accurately. With each new advancement in technology, we are able to decrease the potential for human error and increase precision. That’s why we find it so important.

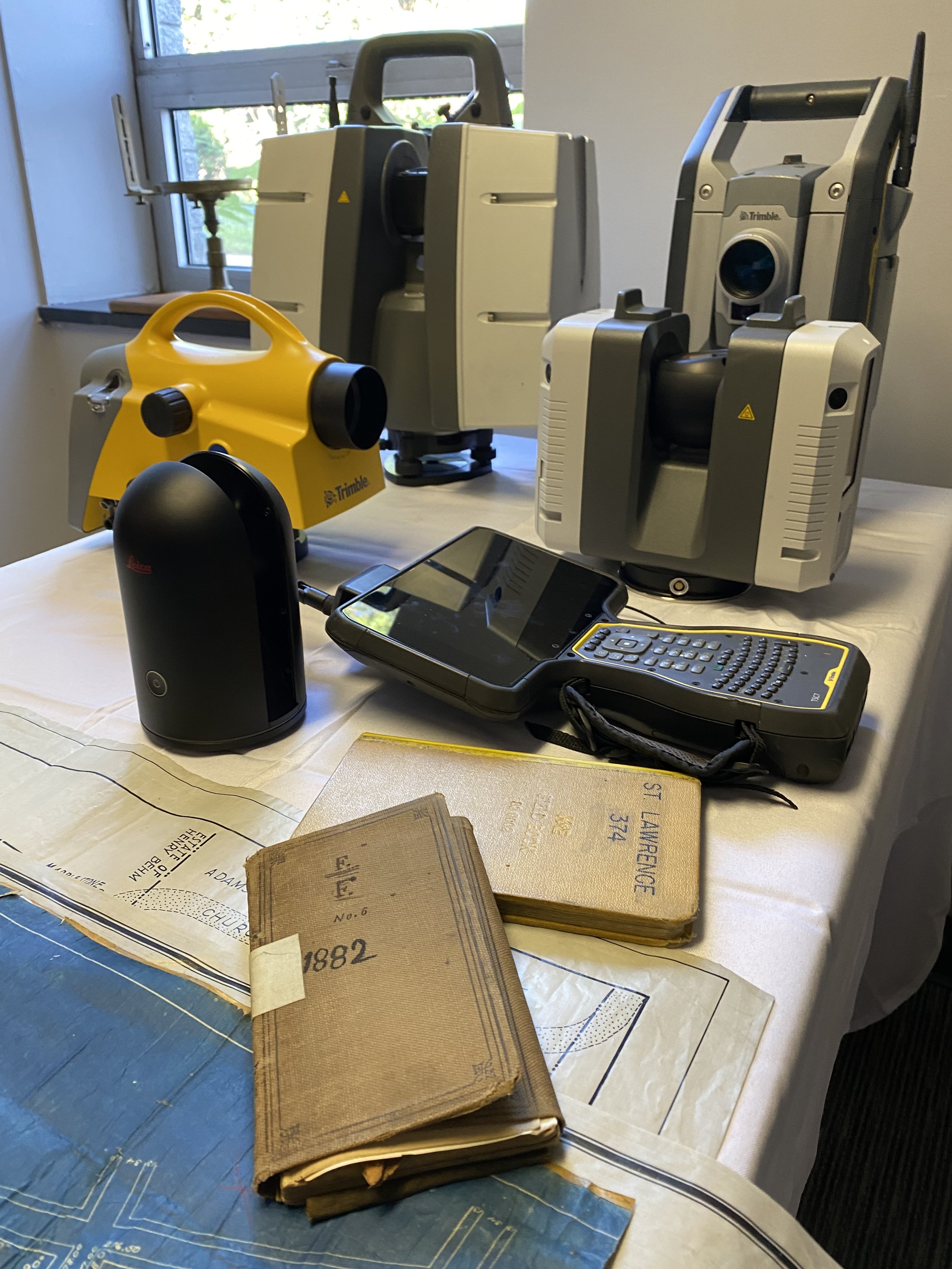

Some of our notable survey and data capture technology upgrades throughout the years:

1932 | In 1932, engineering and surveying was a manual process. It started with paper and pencil, capturing data and measurements in the field and then drawing out plans and designs by hand.

1972 | Hewlett Packard's 3800A Distance Meter opened a new era in surveying for Spotts, Stevens and McCoy, Inc. This new equipment allowed measurements to be made up to 10,000 feet with an accuracy of +(0.01 feet +0.01 ft. per 1000 ft.). This instrument replaced the measuring tape when large tracts of land were to be surveyed.

1994 | CADD Department Upgrades Equipment: Our team added 5 new CADD stations and replaced its old Calcomp pen plotter with a new HP650C Design Jet color printer reducing printing time from 1 hour to six minutes.

1995 | SSM added state-of-the-art Trimble Global Positioning System (GPS) equipment. GPS uses satellite telemetry to obtain precise three-dimensional positions on the earth's surface. Since GPS does not rely on optical line of sight conditions, it can be used day or night, over long distances and under all weather conditions. This equipment now gave SSM the capability of providing land development control, groundwater monitoring well locations, and aerial photography orientation points as well as three-dimensional networks for municipal mapping and GIS applications.

2007 | SSM purchases its first high-definition scanner. Coined Lucille by the staff, the high-definition laser scanning technology provided a non-intrusive method to obtain three-dimensional geometry measurements and models of existing structures and sites for both large and small-scale projects. Today our scanners have evolved, some capturing 1,000,000 data points in just a second.

2012 | SSM purchases its first drone and invests in training/certifying staff as FAA Certified Remote Pilots. We use Drone Flight Services and High-Definition Laser Scanners to obtain models and measurements of existing structures and sites. This non-intrusive technology saves time while raising the bar for high-definition precision all size projects such as campus master planning, historic building preservation and industrial development or impact sensitive agricultural and preserved lands.

2022 | In addition to our Leica P40 scanner, our most recent scanner upgrade, the Leica RTC360, empowers our scanner team to document and capture project data in 3D, while improving efficiency and productivity in the field. Our implementation of Leica Cyclone and Register 360 post processing software allows our scanner team to export point cloud data in a variety of formats.