Focus on the core.

It takes a lot to make and market a product. It also takes a lot to assure regulatory compliance as well as address needs such as increased capacity, routine maintenance and facility expansion. That's why manufacturers of everything from chocolate to steel turn to SSM when it comes time to secure prime locations, plan more efficient warehouses and distribution centers, conduct feasibility studies, upgrade utilities and building systems, improve traffic flow and expand operations. By taking the lead on the facilities engineering side, we enable manufacturers to focus more on their core business.

HIGHLIGHT PROJECTS

Members of our Energy and Sustainability Services department performed a ‘building tune-up’ at the Juvenile Justice Center to identify opportunities for conserving energy and water usage. This evaluation was conducted as a pilot for the City of Philadelphia, for the development of Building Energy Performance Policy Ordinance and program guidelines. (BEPP)

SSM developed a plan to convert a chilled water plant consisting of two independent chilled water systems comprised of 2 – 600 ton chillers (N+1) and associated pumps and 2 – 250 ton chillers (N+1) and associated pumps to a single system consisting of 3 – 400 ton chillers and associated pumps.

SSM prepared construction documents for the installation of a dual fuel 1,200 HP boiler to replace a 67 year old water tube boiler.

Our services to NWNA have included providing ventilation studies at these three facilities to evaluate airflow, contaminant migration, and temperature control.

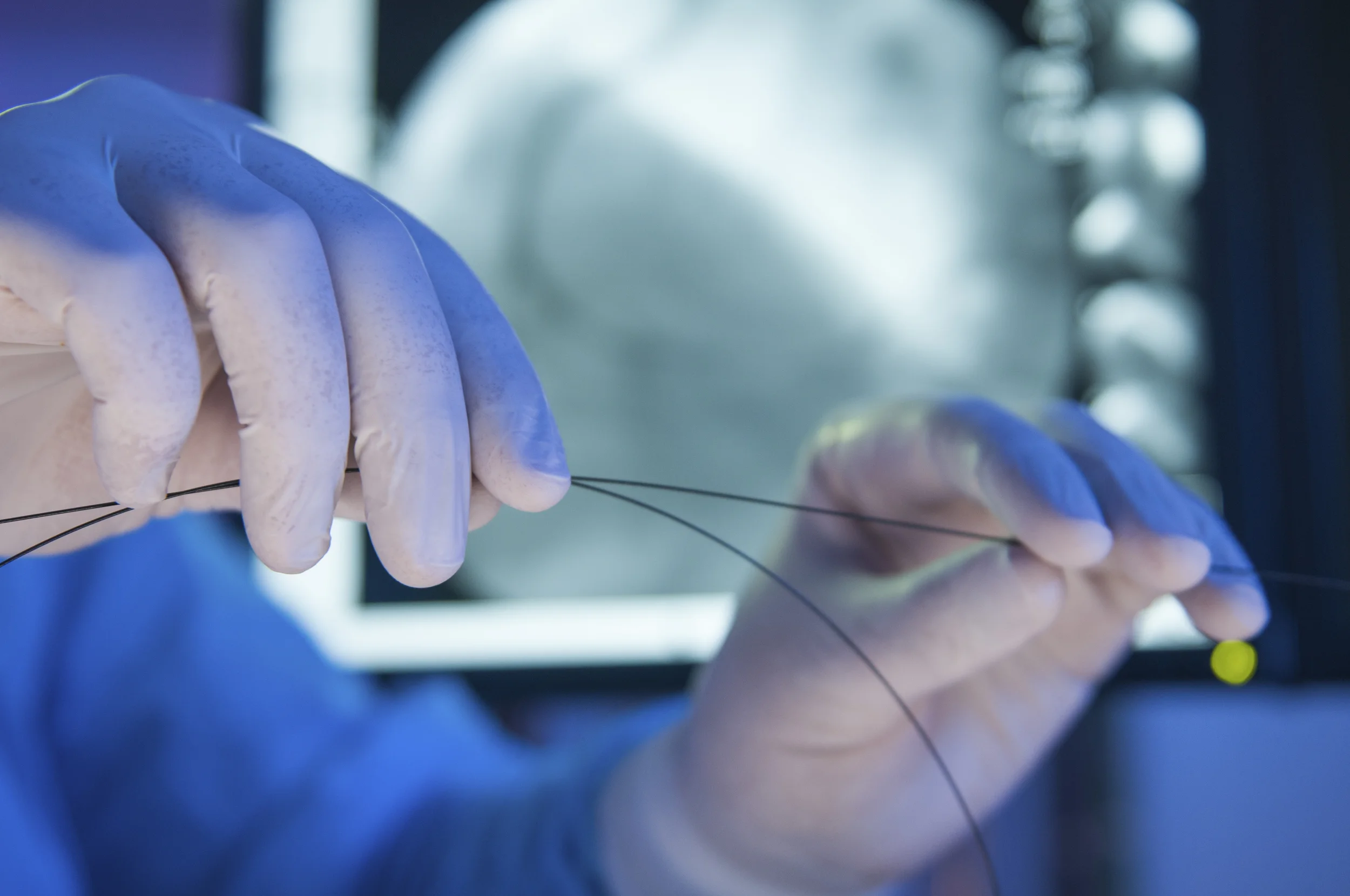

SSM provided engineering services for a project that included conversion of an existing building to use as manufacture of sterile product used in the pharmaceutical industry, warehousing, and office space.

SSM has provided engineering services to Blue Ridge for many years covering a wide variety of services.

As part of an ongoing consolidation of space and expansion of research capacity SSM provided architectural engineering and construction management assistance to create a new research and laboratory section at the facility.

SSM analyzed the chilled water system serving a 27,600 square foot manufacturing cleanroom in the Corporate Headquarters Facility.

NEWSFEED